Are There Environmental Standards for Protective Films on Building Materials?

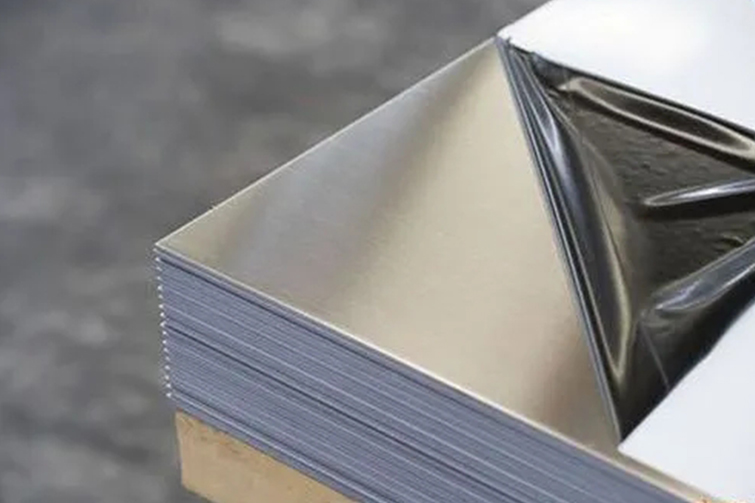

The construction industry is increasingly focusing on sustainability, and the materials used in building projects are no exception. Protective films, which are commonly applied to building materials to prevent damage during transport and installation, play an important role in preserving both the aesthetic and functional integrity of these materials. But as environmental concerns become more prominent, the question arises: Are there environmental standards for the protective films used on building materials? The answer is yes, and these standards are crucial for ensuring that protective films do not harm the environment while still fulfilling their intended function.

1. Material Composition and Biodegradability

One of the key environmental concerns regarding protective films is the material they are made from. Traditionally, many protective films have been made from plastic, particularly polyethylene (PE), polyvinyl chloride (PVC), or polypropylene (PP). These materials are durable and effective for protection but pose environmental risks if not properly disposed of, as they are not biodegradable and can contribute to plastic pollution.

To address this, many manufacturers have begun to develop protective films made from biodegradable or compostable materials. These films break down more easily in the environment and reduce the long-term impact on landfills and ecosystems. Environmental standards often encourage or mandate the use of materials with a lower environmental footprint, such as biodegradable plastics or films derived from renewable resources.

2. Toxicity and Safety

In addition to biodegradability, another important environmental standard for protective films is the absence of harmful chemicals. Some traditional films may contain additives or plasticizers, such as phthalates or heavy metals, which can leach into the environment and pose risks to human health and wildlife. Modern environmental standards emphasize the need for protective films to be free from toxic substances that can harm the environment or human health.

Many international environmental certifications, such as the EU’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the U.S. EPA’s (Environmental Protection Agency) standards, require that protective films used in construction be free from hazardous substances. These certifications ensure that the films meet strict safety criteria for both their production and disposal.

3. Recyclability and Circular Economy

Recyclability is another critical factor in the environmental standards for protective films. A key goal of many environmental regulations is to encourage the development of a circular economy, where materials can be reused or recycled instead of being disposed of after a single use. Protective films that are recyclable can be processed and reintroduced into the production cycle, reducing waste and conserving resources.

Manufacturers are increasingly producing recyclable protective films, often marked with recycling symbols that indicate the type of plastic used. This allows construction companies to dispose of used protective films in an environmentally friendly way, supporting recycling programs and reducing the burden on landfills.

4. Energy Efficiency in Production

Another component of the environmental standards for protective films is the energy efficiency of their production. The manufacturing process for traditional plastic films often consumes large amounts of energy, contributing to greenhouse gas emissions and other environmental impacts. Modern environmental standards encourage the use of energy-efficient production methods and renewable energy sources to reduce the carbon footprint of protective film manufacturing.

Some manufacturers have made significant strides in reducing the energy required to produce protective films, using techniques like advanced extrusion processes or sourcing renewable energy for their factories. This shift not only benefits the environment but also aligns with global efforts to combat climate change.

5. Waste Management and Disposal

The proper disposal of protective films after their use is a key concern in construction projects. Environmental standards often mandate that companies implement effective waste management practices to minimize the impact of discarded films on the environment. This can include recycling, composting biodegradable films, or ensuring that non-recyclable films are properly incinerated to prevent pollution.

Construction companies are encouraged to work with waste management services that comply with environmental standards and support the proper disposal or recycling of protective films. This helps reduce the environmental impact and supports sustainable building practices.

6. Global Certifications and Standards

Many protective films used in building materials must adhere to global environmental certifications and standards. Some of the key certifications include:

REACH (EU): Regulates the use of chemicals in products to ensure they do not harm human health or the environment.

RoHS (Restriction of Hazardous Substances): Ensures that electrical and electronic products, including protective films for building materials, are free from harmful substances like lead, mercury, and cadmium.

ISO 14001: A global standard for environmental management systems, which companies must comply with to minimize their environmental impact.

These certifications and standards provide guidance and regulation to ensure that protective films used in construction meet environmental criteria and contribute to sustainability goals.

Conclusion

As the construction industry continues to prioritize sustainability, protective films for building materials must also evolve to meet environmental standards. These standards address the material composition, toxicity, recyclability, and energy efficiency of protective films, ensuring they are safe for the environment and human health. By adhering to these regulations and using eco-friendly protective films, construction companies can play a crucial role in reducing waste, conserving resources, and promoting a greener future.