Is a Stainless Steel Protective Film Necessary?

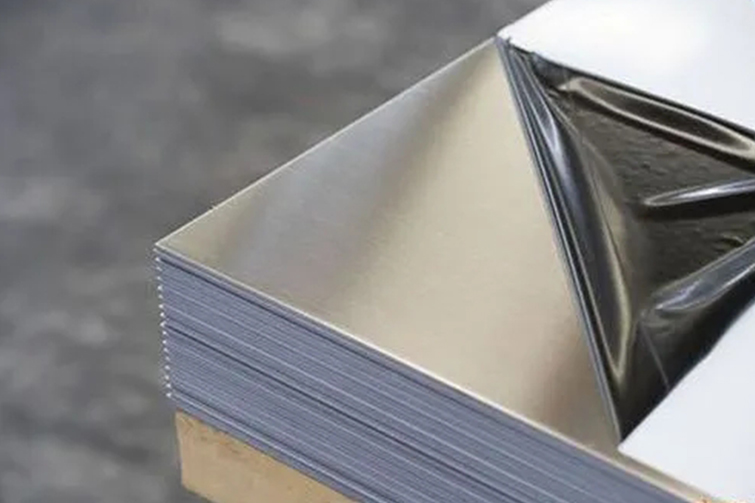

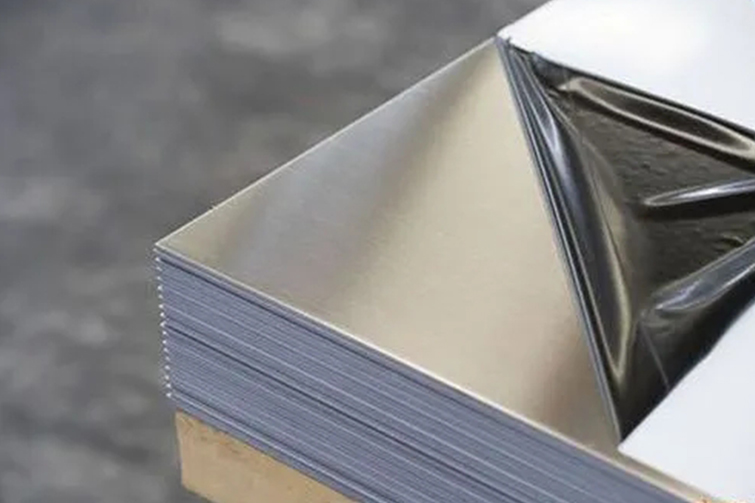

Stainless steel is known for its durability, sleek appearance, and resistance to corrosion, making it a popular choice for appliances, construction materials, and industrial applications. Despite these inherent qualities, many manufacturers and consumers opt to use a protective film on stainless steel surfaces during production, shipping, and installation. But is this protective film truly necessary? Let’s explore the importance of a stainless steel protective film, when it should be used, and its benefits.

1. Why Use a Protective Film on Stainless Steel?

Although stainless steel is highly resilient, it is not entirely immune to scratches, dents, and other surface damage. During manufacturing, transportation, and handling, the metal can be exposed to various hazards that might compromise its pristine finish. Here are several key reasons why a protective film is necessary for stainless steel:

Protection Against Scratches: Stainless steel surfaces are prone to scratching when exposed to tools, equipment, or rough handling. A protective film acts as a barrier, absorbing potential abrasions and preserving the surface underneath.

Dust and Contaminant Prevention: In industrial environments, stainless steel may be exposed to dust, dirt, and chemical contaminants. The protective film keeps these particles from sticking to the surface, preventing staining or surface corrosion.

Prevention of Fingerprints and Smudges: Especially in home appliances, fingerprints and smudges are a common concern with stainless steel. A protective film helps keep the surface clean until installation is complete.

Protection During Installation: Stainless steel surfaces often endure the most stress during the installation process. Scratches from tools, unintentional scuffs, and exposure to other construction materials can leave permanent marks. The film ensures that the stainless steel stays intact during these high-risk stages.

2. When Should a Protective Film Be Used?

The use of a protective film depends largely on the purpose and environment where the stainless steel is being used. Here are common situations where a protective film is beneficial:

During Manufacturing: In manufacturing processes involving cutting, welding, or polishing, a protective film ensures the surface is not damaged. It prevents scratches, marks, and residue buildup from tools and machinery.

Shipping and Transportation: Shipping can subject stainless steel products to rough handling, vibration, and jostling, which can lead to dents or scratches. The film provides an extra layer of cushioning to protect the product.

On-site Installation: For construction materials like stainless steel panels or countertops, installation often involves sharp tools, rough surfaces, and contact with other heavy materials. The protective film acts as a shield until the product is securely in place.

3. Advantages of Using a Stainless Steel Protective Film

Cost Savings: Repairing or replacing scratched stainless steel surfaces can be expensive. A protective film minimizes the risk of surface damage, reducing the need for costly repairs or rework.

Enhanced Aesthetics: The pristine look of stainless steel is one of its most appealing features, particularly in high-end kitchens, commercial spaces, and industrial design. A protective film ensures that the surface retains its flawless appearance until it's ready for use.

Ease of Removal: Protective films are designed to be easily peeled off without leaving any residue. This means you can protect the surface throughout the process without worrying about difficult cleanup afterward.

Versatility: Protective films are available in different thicknesses and adhesive strengths, allowing you to choose the right level of protection for the application.

4. Situations Where a Protective Film May Not Be Necessary

While protective films are useful in many cases, there are instances where they may not be needed. For example:

Indoor, Low-Traffic Areas: If stainless steel is installed in areas with minimal risk of scratches, contamination, or rough handling, such as wall panels in low-traffic areas, a protective film may not be required.

Permanent Fixtures with High Durability: For stainless steel fixtures or appliances designed for heavy-duty use, where the surface finish is less critical, skipping the protective film may not have significant consequences.

5. Conclusion

A stainless steel protective film is an essential step in safeguarding the surface of this versatile material during production, transportation, and installation. It protects against scratches, dirt, and handling damage, ensuring the material maintains its sleek appearance and integrity. While it may not be necessary in all situations, the advantages far outweigh the potential risks of damage in most cases. For industries and consumers seeking to preserve the quality and longevity of their stainless steel products, using a protective film is a wise investment.