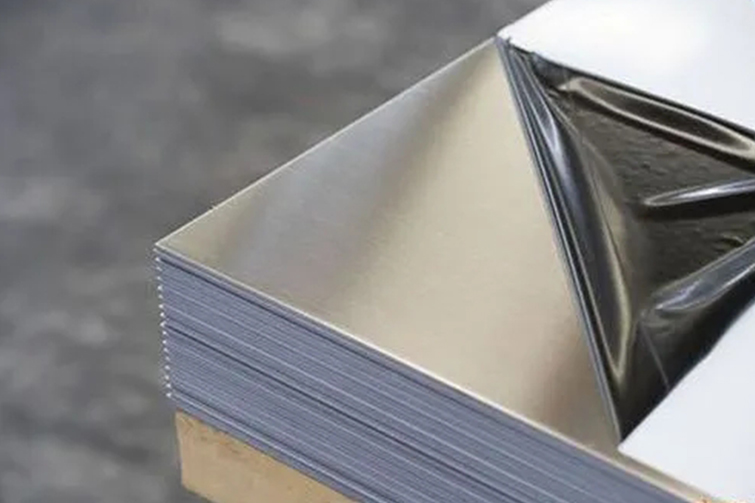

The Importance of Protective Film for Building Materials Before Use

In the construction process, the quality and appearance of building materials directly impact the final outcome and durability of the project. To ensure that materials are not damaged during transportation, storage, or installation, many building materials are covered with a protective film at the factory. This protective film not only shields the materials from environmental factors but also preserves their original appearance and performance. So, how important is it to use a protective film for building materials before they are utilized? Let’s explore its necessity and advantages in detail.

1. Prevents Scratches and Damage

Building materials such as glass, metal, and wood often undergo long-distance transportation and complex construction processes. During this time, materials are prone to scratches or damage due to tool friction, bumps during handling, or improper operation. A protective film provides a barrier that absorbs potential damage, protecting the surface of the material from scratches and wear.

2. Dust and Dirt Resistance

Construction sites are usually filled with dust, dirt, and other contaminants. If no protection is in place, these pollutants can easily adhere to the surface of materials, particularly smooth surfaces like glass or stainless steel. This not only affects the aesthetic but can also impact the material's functionality. A protective film acts as a shield, preventing dust and dirt from sticking and ensuring that the materials remain clean and ready for use.

3. Prevents Chemical Corrosion

In some construction environments, various chemicals such as cleaners, paints, and adhesives are used. If these chemicals come into contact with the surface of building materials, they may cause corrosion, discoloration, or other irreversible damage. A protective film can serve as a chemical barrier, preventing harmful substances from damaging the material, and ensuring that the material retains its physical properties and appearance.

4. Reduces Repair and Replacement Costs

If building materials are damaged during transportation or construction, it will not only increase repair costs but may also lead to project delays, affecting the overall schedule. The protective film, acting as an additional protective layer, greatly reduces the risk of material damage, thereby decreasing the need for repair or replacement and saving time and money on the project.

5. Improves Construction Efficiency

Using a protective film allows construction workers to handle materials more confidently without worrying about accidentally damaging the material surface. This not only reduces the time spent on inspections and repairs but also enhances construction efficiency, ensuring that the project stays on track.

6. Extends the Lifespan of Materials

Some building materials, such as stainless steel and aluminum, have strong durability and resistance to corrosion. However, prolonged exposure to harsh environments or frequent use can still lead to aging or wear. A protective film can extend the lifespan of these materials by reducing the negative impact of external environments, allowing them to perform better over time.

7. Facilitates On-site Management and Installation

On construction sites, different materials are required at various stages of the project. The protective film not only protects materials from damage before use but also facilitates on-site management. Workers can easily remove the protective film when needed and use clean and undamaged materials, making the installation process more efficient.

8. Easy Removal Without Residue

Modern protective film technology is highly advanced, and many protective films can be easily peeled off after use without leaving any adhesive residue or marks on the material surface. This ensures that the materials maintain their aesthetic and functional integrity. Construction teams can confidently use protective films without worrying about additional cleaning.

Conclusion

Applying protective film to building materials before use is a critical protective measure. It not only prevents damage during transportation and construction but also improves construction efficiency, reduces repair costs, and extends the lifespan of materials. In high-end construction and precision projects, the importance of protective film becomes even more apparent. By using protective film, materials remain in optimal condition before use, ensuring the final quality and aesthetics of the construction project.